January 28th, 2026 - Zed van der Vyver

The Ultimate Guide to Structural Steel in Thailand: Building a Home That Lasts

If you are planning to build a "forever home" or a modern loft in Thailand, steel is going to be your best friend. It isn’t just heavy metal; it is the high-strength framework that keeps your roof from sagging during a monsoon and your floors from cracking over time.

Think of steel like the skeleton of your house. Just as your bones support your weight and protect your organs, the steel in your walls and roof supports the concrete and keeps everything standing straight against gravity and tropical winds.

1. The Technical Breakdown: Understanding the "Moving Parts"

Before you place an order with a local supplier, you need to know that not all steel is created equal. Using the wrong type is like using toothpicks to hold up a bowling ball.

The Two Main "Jobs" of Steel

-

Reinforcement (Rebar): These are the bumpy rods hidden inside your concrete columns and floors. Concrete is great at being squashed (compression) but terrible at being pulled (tension). Rebar provides the "muscle" so the concrete doesn't snap.

-

Structural Sections: These are the visible beams (like H-beams or C-channels) used for modern "steel-frame" houses or roof trusses. Why it matters: They allow for wide, open spaces without needing a forest of support pillars.

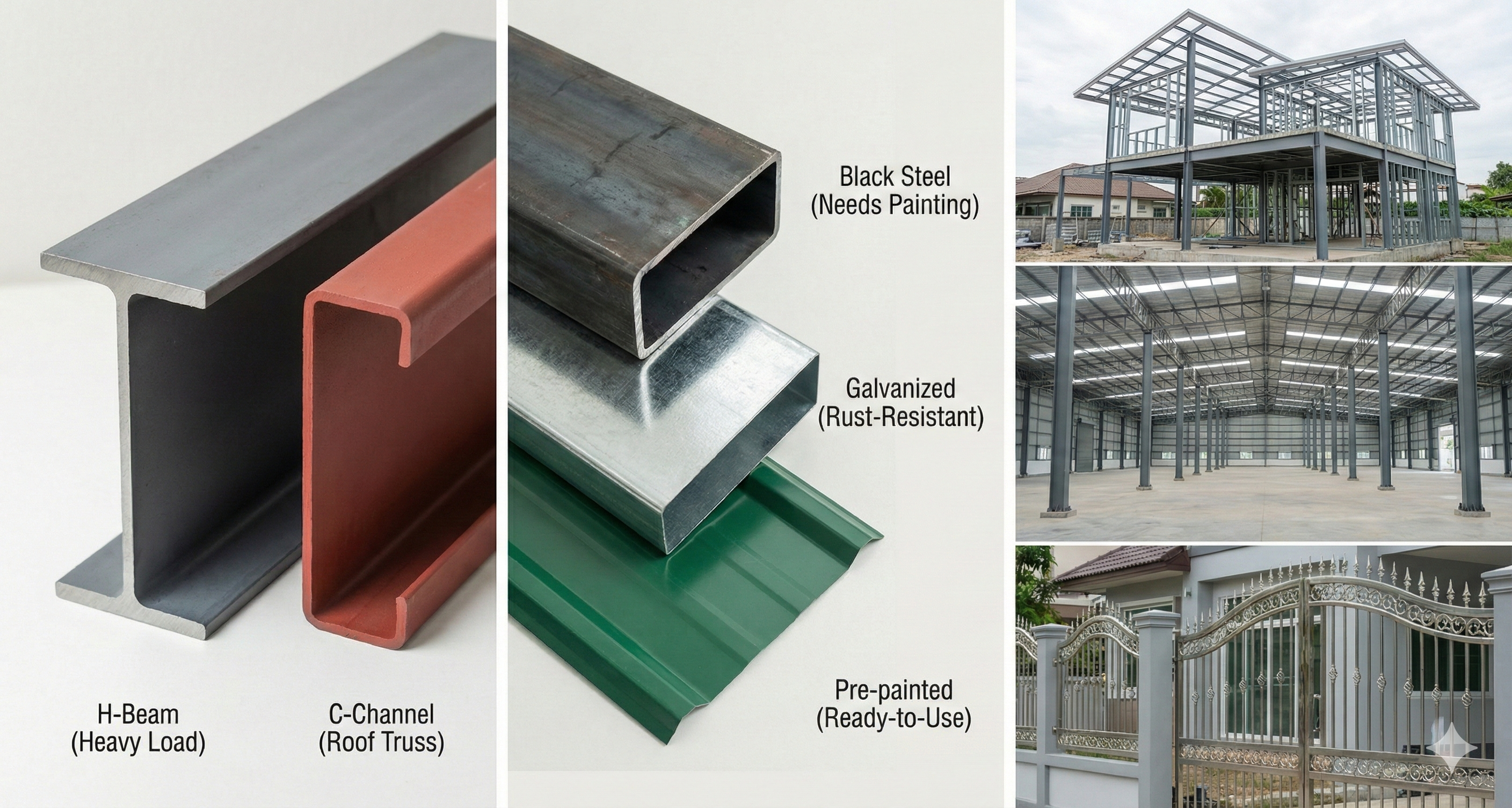

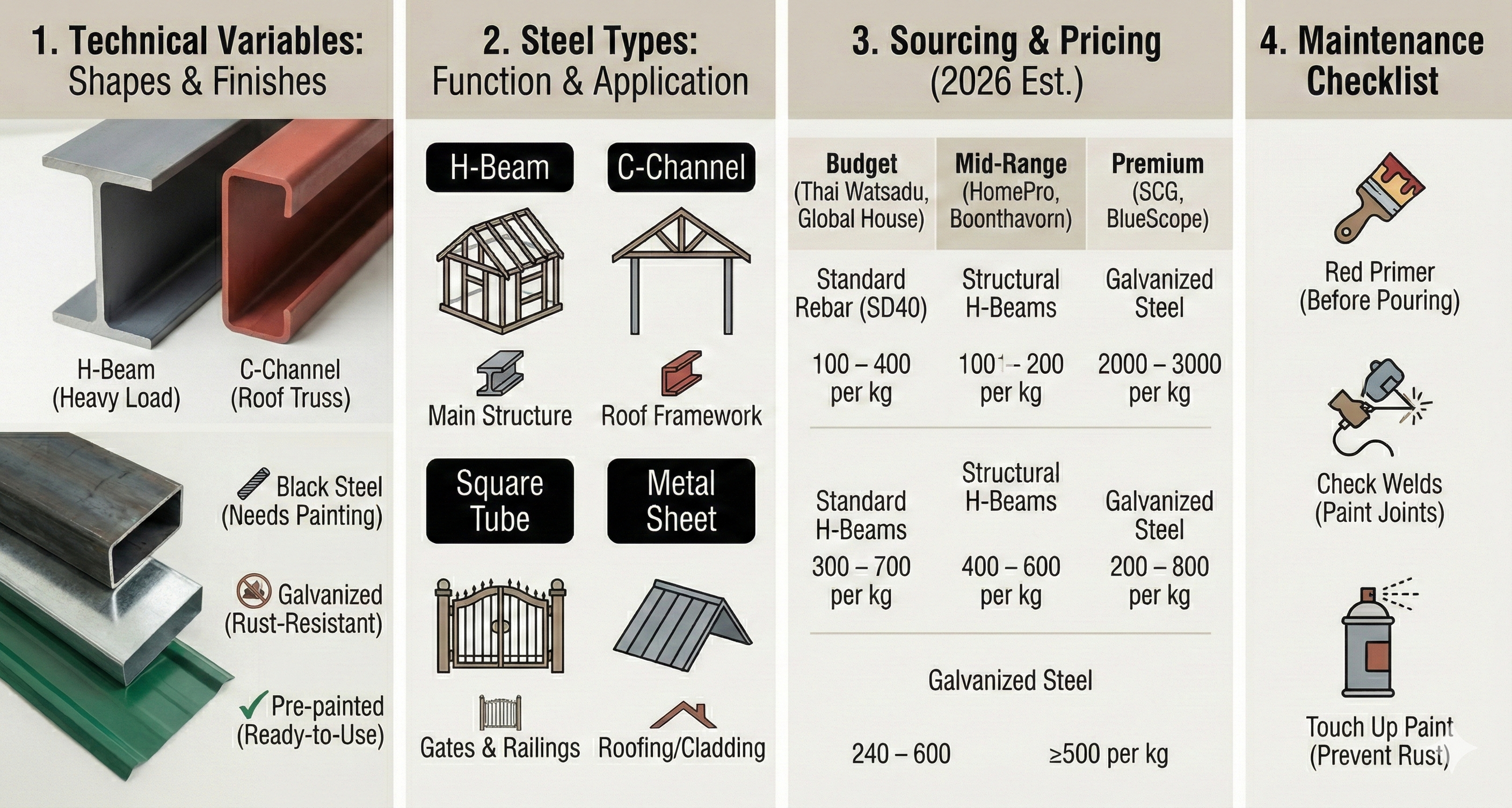

Finish & Protection: Fighting the Humidity

-

Black Steel: Standard raw steel. It’s the cheapest option but will rust within days in Thailand’s humidity if not painted immediately.

-

Galvanized Steel: Steel coated in a layer of zinc. Think of this like permanent rain gear. It’s much more resistant to rust and is the gold standard for roof frames.

-

GI (Galvanized Iron) Pipes: Often used for fences or light structures. They are pre-protected and don't require heavy painting.

2. Steel Types: Which One Fits Your Project?

Choosing a steel shape is about matching the "shape" to the "stress" it will face.

| Steel Type | Best Use Case | The "Why it Matters" Factor |

| Deformed Bar (DB) | Main House Columns | The "ribs" on the bar grip the concrete like a handshake, preventing it from slipping. |

| H-Beam / I-Beam | Main Support Beams | These are the heavy hitters. They can carry massive weight over long distances without bending. |

| C-Channel | Roof Framework | Shaped like a "C," these are lightweight but stiff. Perfect for holding up heavy roof tiles or metal sheets. |

| Square Tube | Gates & Railings | Easy to weld and paint. Great for "finishing" touches rather than the main structure. |

| Metal Sheet | Roofing | Thin, coated steel. It’s the "skin" of your roof—lightweight and sheds rain quickly. |

3. Sourcing & Market Data: Where to Buy in Thailand

Steel prices in Thailand fluctuate based on the global market, so it’s always better to buy in "phases" rather than all at once if the market is volatile.

Top Suppliers

-

Budget (The DIY Route): Thai Watsadu and Global House. Ideal for buying rebar and standard C-channels in small to medium quantities. They often have "ready-to-go" stock.

-

Mid-Range (Service-Oriented): HomePro and Boonthavorn. Best for specialized steel products like high-end fencing or decorative metalwork.

-

Premium (The Professional Grade): SCG (Siam Cement Group) and BlueScope. These are the industry leaders. If you want certified "high-tensile" steel or premium coated roofing with a 30-year warranty, these are your go-to brands.

2026 Pricing Tiers (Estimated)

Prices are estimated per kilogram (kg) or per ton for bulk orders.

| Quality Tier | Estimated Price (THB/kg) | What You Get |

| Standard Rebar (SD40) | ฿24 – ฿28 | Standard strength for 2-story homes. |

| Structural H-Beams | ฿30 – ฿38 | High-load capacity, usually hot-rolled. |

| Galvanized Steel | ฿35 – ฿45 | Rust-resistant coating included; saves on labor. |

Pro Tip: In 2026, many contractors prefer "Pre-zinc" steel. It costs about 15% more than black steel but saves you a fortune in labor costs because you don't have to hire someone to scrape off rust and apply red oxide primer.

4. Maintenance: The "Layman's" Checklist

Steel is tough, but in a tropical climate, "cancer" (rust) is its only enemy. Here is how to keep your home's skeleton healthy:

-

The "Red Primer" Rule: If you see any orange or brown spots on your steel before the concrete is poured, scrub it off and re-prime it. Rust hidden inside concrete can expand and cause the concrete to "explode" (spalling).

-

Check the Welds: The joints where two pieces of steel meet are the weakest points for rust. Ensure your welder paints over every joint with anti-rust spray immediately after the metal cools.

-

Touch Up Your Roof: Once a year, use a ladder to check the steel supports of your roof. If you see peeling paint, a quick 200-baht can of spray paint can prevent a 50,000-baht repair later.

5. Summary & Next Steps

Building with steel in Thailand is a smart move for speed and strength. For a standard home, prioritize DB12 or DB16 deformed bars for your columns and galvanized C-channels for your roof. This combo offers the best balance of safety and rust protection.