January 28th, 2026 - Zed van der Vyver

The Ultimate Guide to Glass in the Home: From Basic Windows to High-Tech Shields

If you’re looking at your windows, shower doors, or table tops, you’re looking at one of the most versatile materials in modern construction. But glass isn't just "clear sand." In 2026, glass has become a high-tech component that controls your home's temperature, protects your family from accidents, and even keeps the neighborhood noise out.

Think of glass like clothing for your house. You wouldn’t wear a thin t-shirt in a snowstorm, and you shouldn’t use "thin" glass in a high-traffic or high-heat area. Choosing the right "outfit" for your openings is the secret to a comfortable, safe, and energy-efficient home.

1. The Technical Breakdown: Understanding the "Moving Parts"

Before you buy, you need to know what’s under the hood. Not all glass is created equal, and choosing the wrong type for the wrong spot can be a costly (or dangerous) mistake.

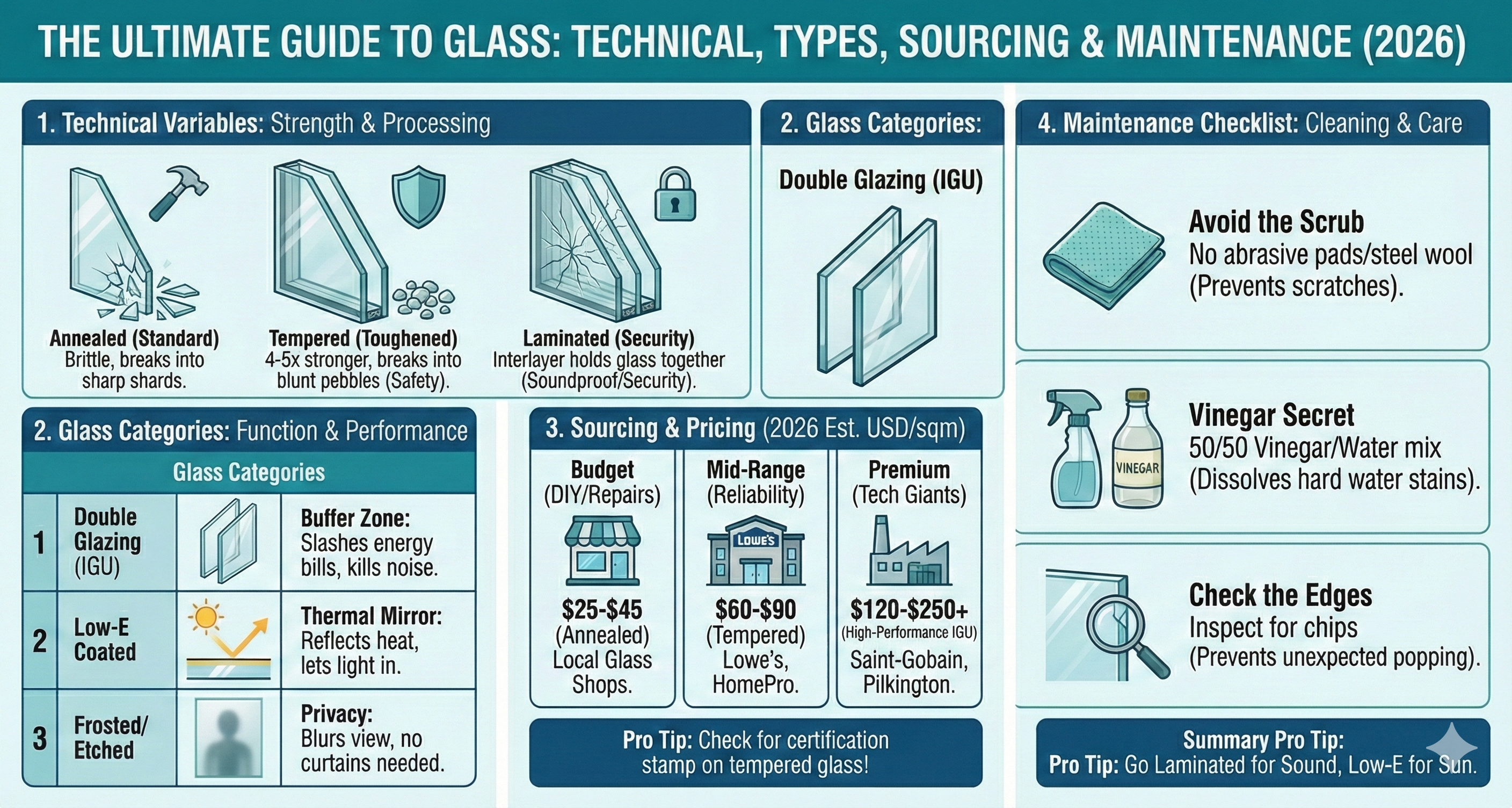

The "Strength" Variables: Processing Types

-

Annealed (Standard) Glass: This is your basic, entry-level glass. It’s cheap but brittle. If it breaks, it shatters into long, sharp "shards." Why it matters: It’s fine for small picture frames, but a "no-go" for doors or low-level windows.

-

Tempered (Toughened) Glass: This glass is heat-treated to be 4–5 times stronger than standard glass. Think of it like a phone screen protector for your house. Why it matters: If it breaks, it crumbles into small, blunt pebbles. This is mandatory for shower screens and sliding doors.

-

Laminated Glass: Two sheets of glass glued together with a plastic interlayer (PVB). Think of it like a car windshield. Why it matters: Even if it breaks, the glass stays stuck to the plastic. It’s the ultimate choice for security and soundproofing.

The "Shield" Variables: Coatings & Additives

-

Low-E (Low Emissivity): A microscopic metallic coating that reflects heat while letting in light. Why it matters: It acts like a thermal mirror, keeping the summer heat out and the winter warmth in.

-

Tinted Glass: Infused with minerals to add color (bronze, grey, green). Why it matters: It acts like sunglasses for your room, reducing glare and UV damage to your furniture.

2. Glass Categories: Which One Fits Your Needs?

Choosing glass is about matching the material to the "mission" of the room.

| Glass Type | Best Use Case | The "Why it Matters" Factor |

| Double Glazing (IGU) | Main Living Areas | Two panes with a gap between them. It’s a buffer zone that slashes energy bills and kills outside noise. |

| Frosted/Acid-Etched | Bathrooms & Offices | Lets light in but blurs the view. Perfect for privacy without needing heavy curtains. |

| Reflective (Mirror) Glass | Sun-facing Walls | It has a "one-way" mirror effect during the day. Stops your home from becoming an oven in direct sunlight. |

| Wired Glass | Fire Exits & Garages | Glass with a wire mesh inside. It’s designed to hold together during a fire, preventing the spread of flames. |

3. Sourcing & Market Data: Where to Buy

Whether you need a single replacement pane or a whole house of windows, knowing where to shop saves time and "buyer's remorse."

Top Suppliers

-

Budget (DIY & Repairs): Local Glass & Aluminum Shops. Every town has one. They are best for quick, custom-cut standard glass for tabletops or broken window panes.

-

Mid-Range (Reliability): Large Hardware Chains (e.g., Lowe’s, Bunnings, or HomePro). Best for standard-sized "off-the-shelf" mirrors and pre-made tempered shower kits.

-

Premium (The Tech Giants): Brands like Saint-Gobain, Pilkington, or AGC. These companies manufacture the high-performance Low-E and acoustic glass used in modern "green" homes.

2026 Pricing Tiers (Estimated)

Prices are estimated per square meter (sqm) for the glass material only.

| Quality Tier | Estimated Price (USD/sqm) | What You Get |

| Economy Annealed | $25 – $45 | Basic 5mm clear glass, no safety features. |

| Standard Tempered | $60 – $90 | 6mm–10mm safety glass, great for bathrooms. |

| High-Performance IGU | $120 – $250+ | Double-glazed, Low-E coating, argon-filled for max insulation. |

Pro Tip: Always check for a certification stamp in the corner of tempered glass. If there’s no permanent etched logo, it might just be standard glass being sold at a premium!

4. Maintenance: The "Layman's" Checklist

Glass is durable, but it’s not invincible. Keep it clear and functional with these three tips:

-

Avoid the "Scrub": Never use abrasive pads or steel wool on glass, especially if it has a coating (like Low-E). You’ll leave permanent micro-scratches. Stick to a microfiber cloth.

-

The Vinegar Secret: For hard water stains on shower glass (that white crusty stuff), mix 50% white vinegar and 50% water. It dissolves the minerals that standard soap can't touch.

-

Check the Edges: The edges are the "Achilles' heel" of tempered glass. If you notice a chip on the edge of a glass door, replace it or have it repaired immediately; a small chip can cause the whole pane to "pop" unexpectedly later.

5. Summary & Next Steps

Selecting the right glass is the most effective way to lower your monthly utility bills and increase your home’s security. If you are building in a loud area, go Laminated. If you are building in a sunny climate, go Low-E.